This post is mainly for those of you who are new to the practice of neon tube bending, and it’s about the difference between lead-free and leaded tubing. Or to be more specific, why you should not practice learning to bend neon using lead glass. Being newer to neon you may not even be aware that there are two different types, but the glass produced to make neon tubing used to contain lead. Around the mid-late 2000s, manufacturing regulations changed regarding the use of lead in glass tubing, and by 2010 only lead-free glass was being produced. It took about 10 years for the inventory of lead glass neon tubing to disappear from the shelves of sign suppliers and distributors, and now if you purchase new glass tubing for neon bending it is only lead-free glass that's available. This is important to know, because how you work the glass in the fire and how it behaves is different between the two types, and it requires adjusting your fires and modifying your bending technique in order to get the same results. It’s not a huge difference between the two types, but it's enough of one that I know of neon benders who got out of the business when the transition happened because they couldn’t adapt to the change. I also know of benders who left the trade years ago but decided to get back into it in recent years and are struggling as they try to re-learn how to bend with lead-free tubing. If you are practicing your bending and don’t know which type of glass you are using, or if you are bouncing back and forth between lead and lead-free while you are bending, you are going to struggle and your progress will be slow and frustrating. By now, you might be wondering what the difference is between lead and lead-free. Simply put, the older tubing that contains lead is easier to bend. It softens at a lower temperature and cools down slower, which gives you a longer working time to shape the bends. Lead-free tubing has a higher melting point and quicker cooling time and requires that you adjust your torches and work a little faster. If you are a beginner, make sure you know which kind of glass you are working with. There are a couple of different ways to check. The first (and probably the most common) is to turn the gas way up on your crossfire. If the glass starts to turn black as it gets hot, it's lead glass. Lead-free tubing does not turn black in the flame, no matter how gassy your flame is. In fact, you’ll need to crank up that gas if you want to get a good nice hot bend with lead-free glass.

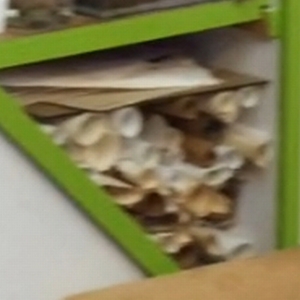

Another way to tell the difference between the two types which doesn’t require heating the glass is to look at the end of the tube. Lead-free tubing looks bluish/green on the end.

Obviously, you’ll need to have a sample of each type of glass in order to compare the two. Here's another example.

Something important to mention when it comes to bending lead-free tubing is that you should make sure to wear didymium glasses. Not only will they protect your eyes from the sodium flare, but it also makes it much easier to see how the glass is heating and when it's time to make your bend.

Even though you can’t buy lead neon tubing new anymore, there is still enough of it out there that you will likely come across some. You can find it in old inventories of closing neon shops, or sometimes it’s donated to teaching facilities that use it for workshops or classes. If you are an aspiring tube bender and get your hands on some old lead glass stock, or maybe even some old dirty tubing that’s not good enough to use for jobs but you think it might be good for practicing your neon bending with, my suggestion to you is…DON’T DO IT!! It will give you a “false sense of ability”, as I’ve heard one seasoned bender put it. If you use lead glass to practice your neon bending (and maybe even get to the point where you’re thinking you are getting pretty good), as soon as you go to buy some neon tubing for a project and all you can get is lead-free, you will quickly find out that you are not as good as you thought and feel as if you are taking steps backward, becoming frustrated as you re-learn how to bend neon. In my opinion, learning to bend neon is hard enough as it is and it’s just not worth the aggravation trying to learn using two different types of glass. Do yourself a favor and set yourself up for success by using only lead-free glass for your bending practice. It makes sense to learn using the material that is currently available to buy (lead-free.) It might be harder, but once you become proficient at bending lead-free neon tubing, then if you do ever have the occasion to use the old lead glass you'll find it easier to adapt and with a simple adjustment of your fires, the glass will bend "like butter."

More information about working with lead-free tubing can be found here. https://www.brillite.com/UserFiles/File/Lead-Free_Tech_Bulletin.pdf

I would love to hear about your experiences working with either type of glass, so feel free to comment below!